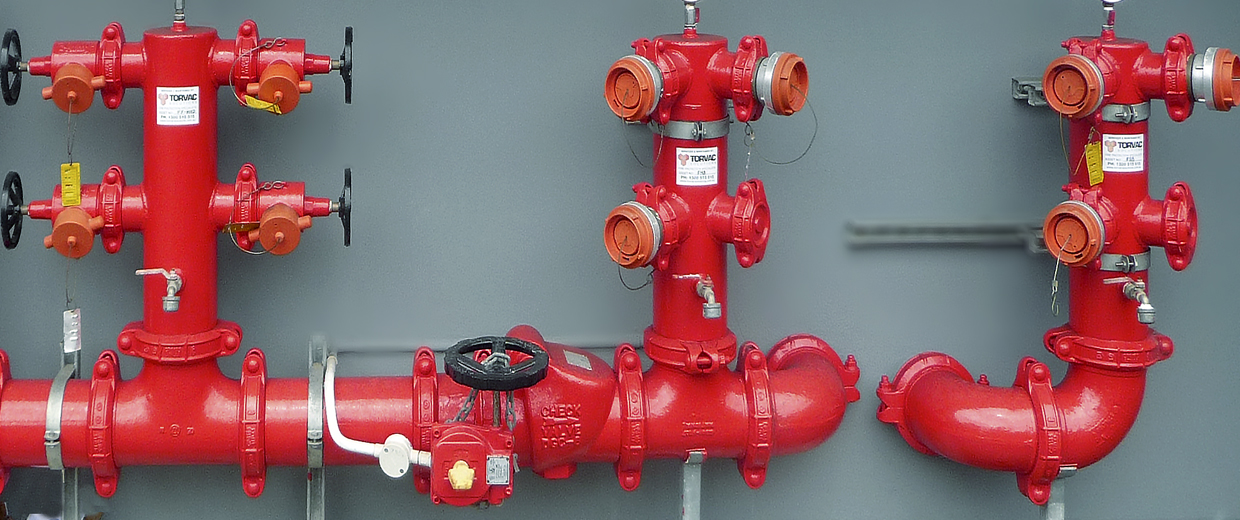

Torvac Solutions can install Fire Hydrant Systems within your building for use by the local fire fighting authority, or qualified personnel, in the event of a fire. Meeting all the requirements of both Australian Standard AS2419.1 and the Building Code of Australia. Torvac can regularly inspect, test and maintain your installed or existing fire hydrant system to ensure it is always ready for use.

Have you ever thought about drinking the water from your Fire Sprinkler or Fire Hydrant Systems?

Don’t laugh… If there is a burst water main in your area, contaminated water can easily be siphoned back into the drinking water without the protection of an adequate backflow prevention system.

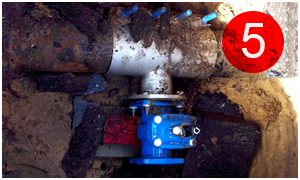

N.S.W Water Authorities require all new and existing buildings with fire hydrant and/or sprinkler systems to be fitted with a backflow prevention valve at the building boundary.

Torvac Solutions can replace your existing fire brigade booster with an all-in-one unit with backflow prevention that conforms to the latest Australian standard and the NSW Plumbing Code of Practice. We can also tailor your installation to suit the building decor…and supply and fit a lockable enclosure if required. Contact Torvac to arrange an inspection of your existing fire system and advise you on the most cost-effective way to install backflow prevention.

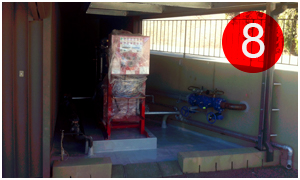

The Santina building in Darling Point, Sydney was subject to a Fire Safety upgrade requirement from local council. As a result, Torvac Solutions installed ta Fire Hydrant System and a hose reel system complete with diesel pump.

Torvac Solutions technicians and engineers worked closely with the building’s architect and a consultant to ensure minimum fuss and a seamless installation.

Such a success was this project, the property manager had stated:

“We have been very satisfied with the finished project and performance of the system. We look forward to maintaining the fire and life safety systems well into the future”.

The photographs taken from the site show the construction of the Hydrant installation at various stages until completion

Interested in talking to Fire Hydrant specialist?